The security and safety of employees are crucial and must be central for every company, whether it involves a high-risk type of work or not.. No matter how big or small the company, the safety and security of employees should always be a priority in the company's operations. As such the company’s operational guidelines should cover the use of PPE.

One of the best preventive measures companies can take is to form strong guidelines regarding Personal Protective Equipment. Let’s delve deeper into what defines Personal Protective Equipment and why it is important.

Just as the name implies, Personal Protective Equipment is a series of clothing designed to protect the whole or parts of the body from unexpected work accidents and reduce the risk for injury and infection.

PPE (Personal Protective Equipment) is vital for all of the company's operational activities, both high-risk and low-risk. PPE can reduce the risk of severe injury or infection caused by work-related accidents. The hazards can be grouped into these categories:

Also read: Types of Hazards You Need to Prevent in Your Workplace.

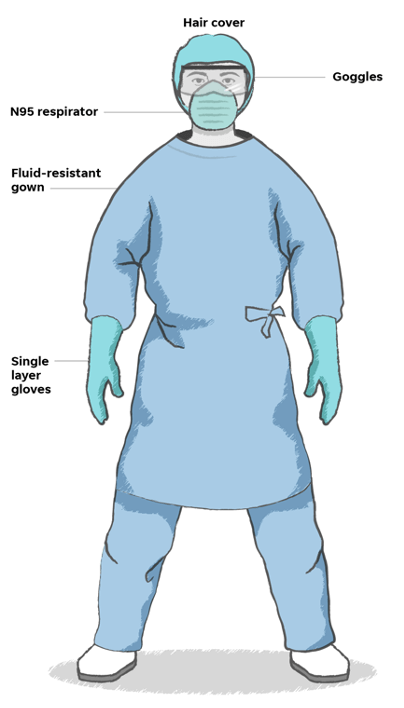

PPE (Personal Protective Equipment) can vary and generally adapts to the needs of an activity or organization. Let’s explore PPE used in the healthcare sector. According to the WHO (World Health Organization) website, PPE can protect health workers from these 2 main hazards:

Almost all industries that have high-risk accident rates require their employees in the field to wear PPE at work or in the working area. This is one of the company's preventive measures to protect their workers in the field. Construction, facility management, healthcare, manufacturing, logistics, and distribution industries have a high requirement for PPE. Each industry will have industry specifications according to their specific work hazards.

Following the examples above, the healthcare industry needs PPE to protect its workers from radiation, viruses, bacteria, and many more.

The PPE most talked about lately is PPE for handling the coronavirus (COVID-19), including surgical masks, particulate filter respirators (such as P2 or N95), goggles and face shields, gowns, and gloves aprons.

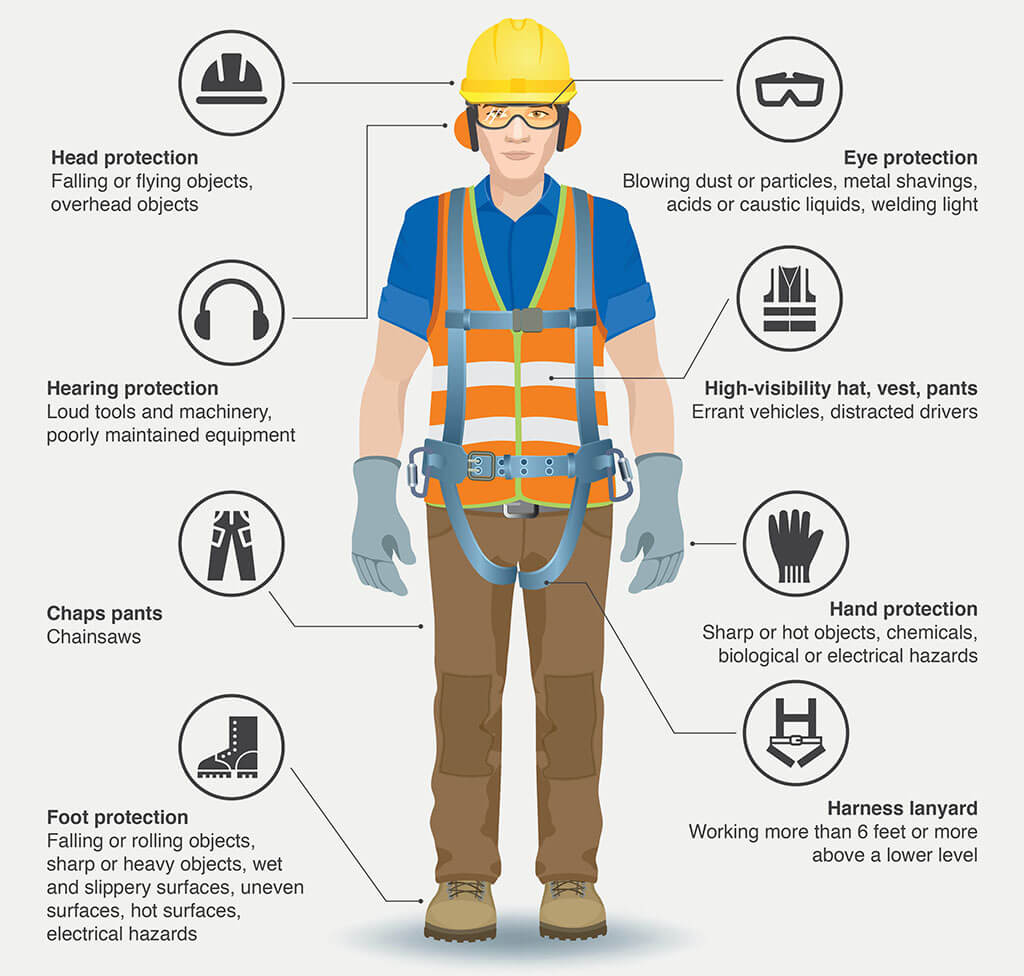

Generally, the PPE used in these industries focuses on physical hazards, safety, and ergonomics because these industries will more often encounter activities that require a strong physique, machinery, and heavy equipment.

Some of the PPE that is often used in the Manufacturing and Construction Industry are:

Generally, the warehousing or distribution & logistics industries use simpler PPE and at a lesser rate than other industries. The PPE commonly used in warehousing, distribution and logistics are:

The presence of PPE has a high impact on the safety and security of workers Not having PPE guidelines threatens the safety of workers, and over time, it can spread to other areas , such as

Therefore, having PPE guidelines is vital for all industries..

To build your PPE guidelines, identify your operating needs, conduct research about the required PPE and its uses, write the guidelines and regulations, and update them regularly. It is similar to building SOPs.

Also read: What you need to pay attention to in creating company SOPs

The set guidelines need to be communicated to the teams and following that you need to ensure employees adhere to them in order to achieve the optimal level of accident prevention.

It is not easy to ensure employees adhere to safety guidelines and that each stakeholder carries out their obligations ..

While creating a detailed checklist for staff to complete and submit regularly to management may be the answer , doing so manually can prove to be very challenging. Automating compliance to safety guidelines will deliver much better outcomes and a much higher level of compliance.

To start creating a checklist, go to https://hellonimbly.com/, select login, and enter your email and password. To create your first account, click here

Next go to (1) Admin > (2) Questionnaires > (3) Add Questionnaire > Create New

Enter the title of the questionnaire in this case (4) PPE (Personal Protective Equipment) Compliance Checklist > (5) Select the assigned department. Go to the question section, (6) enter the question category (Head, Body, Foot protection, etc.) > and finally (7) type in the question.

You can add questions by clicking the number 8 button above, and add categories by clicking the number 9 button. In the number 10 area you can view all the questions you have created which you can easily drag and drop to rearrange the order.

Since now you are using Nimbly as your Digital Checklist software, your daily operational processes will become automated. By doing so, you don’t have to worry about your employees' compliance anymore. Your employees will be notified daily to do the checklist, and you can measure their performance objectively through the Nimbly Admin Dashboard.

Your employees daily audit duration will be 52% faster, and overall employees’ compliance will become 97% out of 100%. (Based on Nimbly Customers Real Results)

If you would like to learn more about Nimbly Technologies, click here; alternatively learn about Nimbly's cool features here .