Nimbly wasn’t just an inspection tool for Astari. It became the system to schedule HSE routines, run shift checklists, and track corrective actions to closure. When an issue is found, it’s logged with evidence, assigned to an owner, and followed up automatically—so managers spend less time chasing and more time preventing repeat issues.

- Schedule routines

HSE routines and shift checklists are scheduled in Nimbly and completed on mobile by assigned owners across the factory. After implementation, Astari reached 97% SOP compliance.

- Capture evidence

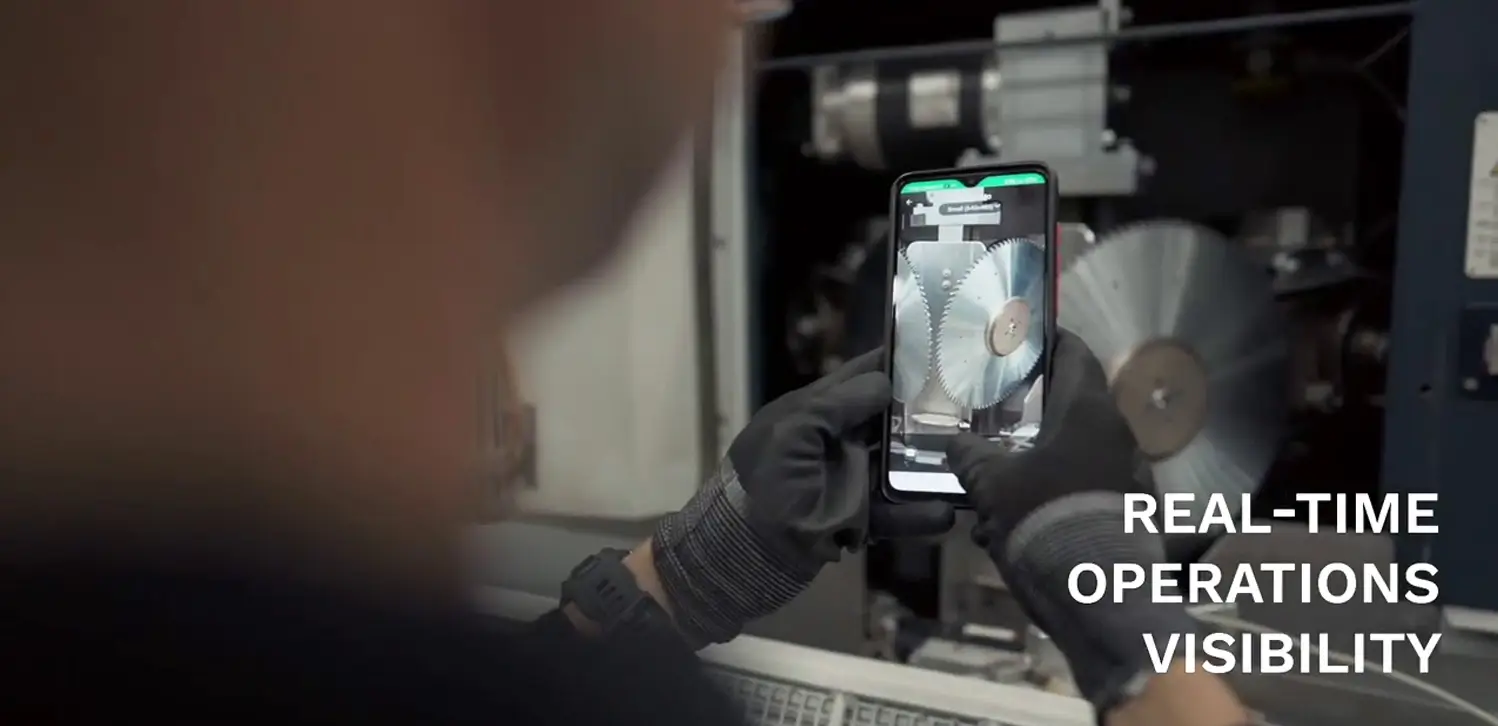

Teams attach required evidence (e.g., live photos) during inspections and requests—making safety findings, inventory needs, and repair work easier to validate and approve without back-and-forth.

- Close the loop

Any finding becomes a tracked workflow: logged as an issue, assigned to the responsible person, and followed through to closure. Managers monitor completed vs missed routines and issues closed on time, helping prevent repeat problems and stay audit-ready.