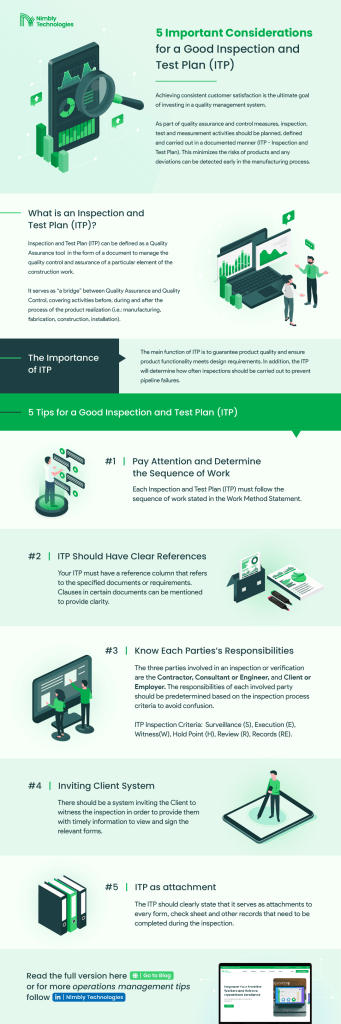

Memenuhi kebutuhan dan kepuasan pelanggan adalah sebuah tujuan akhir dari sebuah sistem manajemen kualitas yang telah disiapkan dan di disain oleh perusahaan.

As part of quality assurance and control measures, inspection, test and measurement activities should be planned, defined and carried out in a documented manner (ITP - Inspection and Test Plan). This minimizes the risks of products and any deviations can be detected early in the manufacturing process.

Let's take a look at what an Inspection and Test Plan (ITP) is and how to create one.

Inspection and Test Plan (ITP) can be defined as a Quality Assurance tool in the form of a document to manage the quality control and assurance of a particular element of the construction work.

It serves as “a bridge” between Quality Assurance and Quality Control, covering activities before, during and after the process of the product realization (i.e.: manufacturing, fabrication, construction, installation).

Hal ini untuk memastikan produk berada pada kualitas yang dapat diterima secara standar dan persyaratan disain.

Baca juga: Hidup sebagai Manajer Penjaminan Mutu Grup di F&B

The main function of ITP is to guarantee product quality and ensure product functionality meets design requirements. In addition, the ITP will determine how often inspections should be carried out to prevent pipeline failures.

Verification of purchased products requires that an organization establish and implement the necessary inspections to ensure that purchased products meet specified purchasing requirements.

Berikut adalah beberapa hal penting yang kami temukan agar Anda dapat membuat Rencana Pengujian dan Pemeriksaan yang baik:

Each Inspection and Test Plan (ITP) must follow the sequence of work stated in the Work Method Statement.

Ini akan membantu Anda dalam mengidentifikasi dan menentukan aktivitas mana saja yang akan diuji sebelum lanjut ke langkah yang selanjutnya.

Your ITP must have a reference column that refers to the specified documents or requirements.

Clauses in certain documents can be mentioned to provide clarity.

The three parties involved in an inspection or verification are the Contractor, Consultant or Engineer, and Client or Employer.

The responsibilities of each involved party should be predetermined based on the inspection process criteria to avoid confusion.

Proses pengujian harus memiliki kriteria untuk setiap Rencana Pengujian dan Perencanaan, seperti:

There should be a system inviting the Client to witness the inspection in order to provide them with timely information to view and sign the relevant forms.

The ITP should clearly state that it serves as attachments to every form, check sheet and other records that need to be completed during the inspection.

Having a document such as an ITP serves as a guideline for your inspections, ensuring that they are carried out correctly. To further assist in inspection processes, it is ideal to have a tool where you can digitalize checklists and have the results available in real time. Nimbly's digital checklist feature allows for a more simplified tool for ceklis digital, and the analytics dashboard allow for real-time visibility and insights into your inspections. Request a free consultation to find out more about how Nimbly Technologies can help you with your Inspection and Test Plan.